WES Quality Guarantee

Solar Panels are extremely reliable items, however they are items generating electricity and therefore we must treat them with the utmost attention. We test for faults that could occur when we inspect a solar panel.

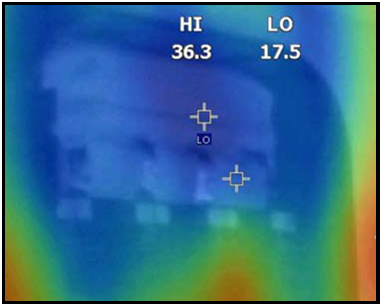

Interconnection of the cells within the solar panel is critical. Poorly controlled soldering processes and materials can contribute to failure, and the overheating of the solar panels. Interconnect systems are subjected to thermal variations which result in daily expansion and contraction and lead to interconnect cracking and failure. Infra-red images we use of solar panels reveal significant hot and cold parts of modules after thermal cycling, indicating interconnect failures.

Junction Boxes

Junction box connections must be secure, must not create dry solder joints that can cause arcing and must be free from flammable sealant materials.

Diodes

By-pass diodes protect the module from overheating when the module is shaded – a condition hard to avoid in many installations. Diode failures are rare but can be replaced simply via the junction box by an approved and competent person. These cannot be replaced in some competitors modules where they are laminated into the module.

Corrosion

Solar panels are subject to harsh environments including moisture and heat, the back sheet should be free from defects, bubbles and scratches that create the opportunity for moisture to penetrate and cause corrosion.